-

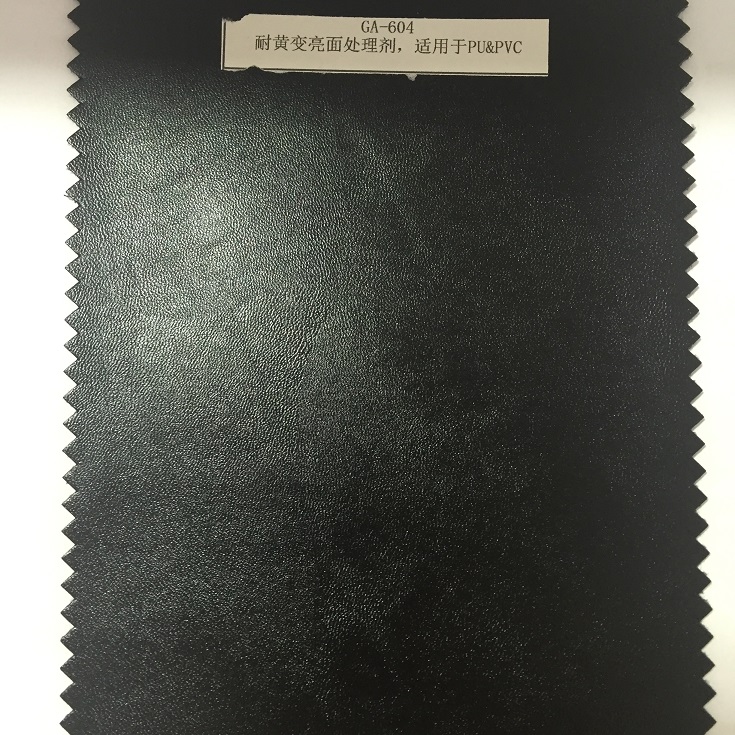

Resistance to yellowing bright surface treatment agent

Item description: GA - 604

1. Summary: resistance to yellowing bright surface treatment agent

(2) : (1) resin: PU resin

(2) solvent: MEK, IPA, EAC

(3) thinner: MEK, TOL

3. Specification: (1) solid ingredients: 13 plus or minus 1%

The CPS viscosity (2) : 300-300/25 ℃

(3) appearance: slightly turbid liquid,

4. Features: resistance to yellow variant bright surface, feel is good, change color bright, can be used in the blade material, suitable for PU, PVC (not hurt foil)

5. Usage: can be used to form and surface, the coating 1 to 3 times, in 100-150 ℃ drying under 1 to 3 min.

6. Note: (1) fire, avoid close to the heat source, fire, and in shade.

(2) the moistureproof, prevent flooding.

(3) after use, should be closed immediately, do not contact with the air time is too long.

(4) the preservation period: three months.

1. Summary: resistance to yellowing bright surface treatment agent

(2) : (1) resin: PU resin

(2) solvent: MEK, IPA, EAC

(3) thinner: MEK, TOL

3. Specification: (1) solid ingredients: 13 plus or minus 1%

The CPS viscosity (2) : 300-300/25 ℃

(3) appearance: slightly turbid liquid,

4. Features: resistance to yellow variant bright surface, feel is good, change color bright, can be used in the blade material, suitable for PU, PVC (not hurt foil)

5. Usage: can be used to form and surface, the coating 1 to 3 times, in 100-150 ℃ drying under 1 to 3 min.

6. Note: (1) fire, avoid close to the heat source, fire, and in shade.

(2) the moistureproof, prevent flooding.

(3) after use, should be closed immediately, do not contact with the air time is too long.

(4) the preservation period: three months.